THE SPECIALIST CONTRACTOR IN LAND & MARINE PILING, CIVIL ENGINEERING

AND MARINE STRUCTURE, JETTY AND HARBOUR CONSTRUCTION

Proposed Design & Build New Liquid Bulk Terminal (LBT4A), Access Bridge and Associated Works at Westport, Pulau Indah, Pork Klang.

LBT4A was the newest addition to boost the overall handling capacity of Westport's’ bustling Liquid Bulk Terminal. The new jetty was intended to receive multiple end users who process both hazardous and Non-hazardous products and serve a big range of vessel sizes to alleviate the traffic of existing liquid jetties. Antara Koh was awarded the design & build contract after the successful delivery of the earlier LBT5 jetty, and our cost-effective EPCC proposal that met the multiple operational needs.

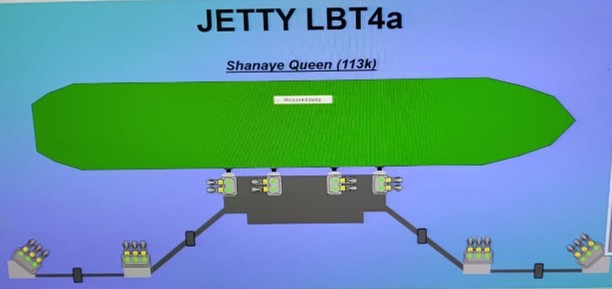

Hydraulic modelling, Mooring Analysis, and Marine Traffic Risk Assessment (MTRA) that included a Full Mission Ship-Handling Simulation (FMSS) were carried out to formulate the optimum jetty configuration. The finally proposed LBT4A has a 275m length berthing front that can handle oil tankers from 3,000DWT to 113,000DWT, and is connected to the shore via a 265m length access trestle with steel pipe rack and concrete roadway. The berth pocket was dredged to -16.5mCD to allow a maximum full-laden draft of 14m. Remote-controlled quick release hooks up to SWL 125T, and a berthing aid system (BAS) with real-time berthing approach monitoring were installed to cater for the mooring needs of vessels carrying dangerous cargoes.

The fire protection system was designed to comply with ISGOTT and NFPA standards. A fire pump station was constructed in the middle of the access trestle, which houses 2 units of vertical turbine seawater pumps that guarantee abundant and uninterrupted supply of water to the fire mains. A foam bladder tank system was connected to the fire mains to deliver the foam solution suitable to extinguish Class B fires. The central platform was equipped with 2 units of tower mounted fire monitors, water curtains, fire hydrants, and shore-to-ship connection for water supply to fire boats. The roadway was designed to allow access for the port’s in-house fire truck to provide additional support.

The fire alarm system comprises various flame and smoke detectors, and manual call points that send the alerts back to the addressable fire alarm panel at the terminal’s central control room. Port operators who are alerted can verify the situation using CCTV cameras along the jetty and control the fire monitors and foam system remotely via the all-in-one table console.

Through active engagement with port’s operation and maintenance department, and involvement in the local authorities’ submission process from the beginning stage of Planning Approval (KM), inputs from various stakeholders were incorporated into the design and construction, to deliver this state-of-the-art liquid jetty to the client.

|

|

|

|

| Left: QRH & LED Display; Right: BAS Software for Real-time Berthing Monitoring & QRH Remote-Control | |

|

|